Process Measurements

We employ innovative technologies and a wide range of instrumentation to support industries in better understanding and controlling their processes, helping not only to enhance the manufacturing process, but also to reduce lost production time, reduce maintenance and reduce other associated costs. Our instruments provide a window into the manufacturing process, providing data to optimize a process efficiency and product quality.

Dust Measurements

-

VIEW 800/820

Certified Multi-sensor dust monitor – category 1 under ATEX / IECEx...

-

VIEW 580

Stand alone Cross Stack optical dust monitor suitable for measuring...

-

VIEW 370

Multi-sensor dust monitor designed for high quality emission...

-

VIEW 273

Multi-sensor dust monitor for indicative emissions trending in...

-

AirSafe 2

Continuous dust monitoring in ambient air: control system areas,...

-

ProSens

Provides continuous measurement values for dust concentration as a...

-

DM 170

The DM 170 Backscatter particulate measurement sensor is designed...

-

QAL 260

Stand alone or networked system option ProScatter™ Backscatter...

Leak and Broken Bag Detection, Filter Performance Measurements

-

LEAK ALERT 65-02

Controller based filter dust leak monitor (0-100%) for filter...

-

LEAK ALERT 73

Stand alone filter dust leak monitor (0-100%) for filter emissions...

-

LEAK ALERT 75/80

Stand alone TÜV approved filter dust monitor suited to the...

-

DUST ALARM 40

Controller based Gross filter failure detector (Broken Bag Filter...

-

DUSTY C

Continuously monitors particulate flow for signs of filter damage...

-

Dusty

Cost effective broken bag detection. A simple solution to identify...

-

LEAK LOCATE 662

The PCME LEAK LOCATE 662 is a digitally networked,...

-

LEAK LOCATE 320

Controller based filter dust leak monitor (0-100%) for filter...

-

PADDY

Paddy has been developed to supply a trending information of...

-

STACK 990

TÜV approved particulate monitor providing high quality emission...

Oxygen Monitoring

Flow Measurement and Detection

Level and Moisture Monitoring

Flame Detectors and Gas Igniters

Engine Exhaust Gas Measurement

-

LGD 2M

Rack 3U monitor using the TDL (Tunable Diode Laser) extractive...

-

BERYL 92M

FTUV Ammonia (NH₃) Analyzer (Fourier Transform) provides ultra-fast...

-

EGAS 2M

The only system allowing the measurement of 1 or 2 independent...

-

EGAS DeNOx

Heated Turnkey Gas Analysis System ideally suited for fast,...

MAIN APPLICATIONS

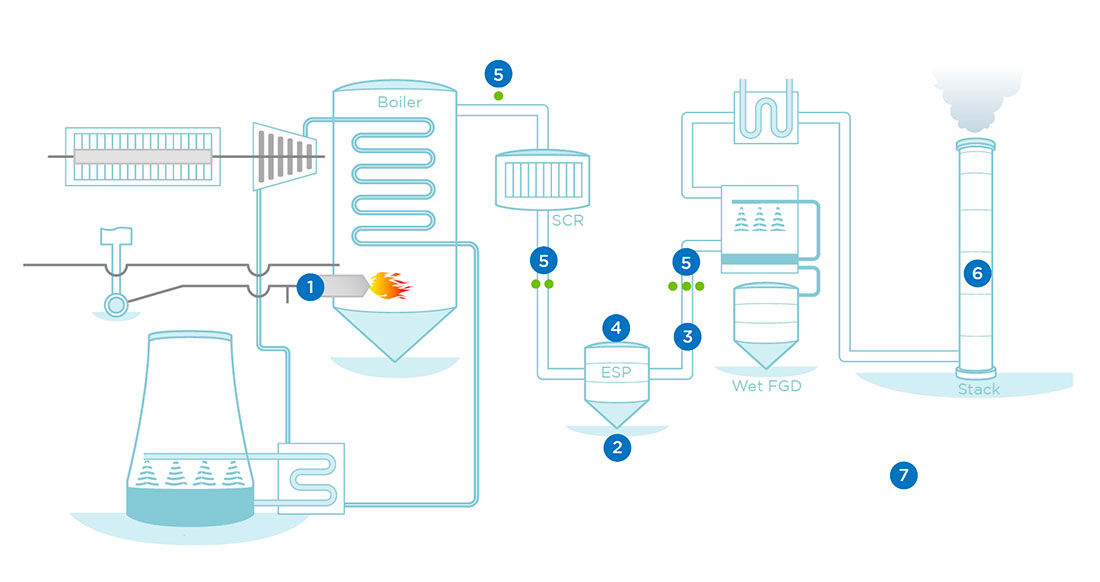

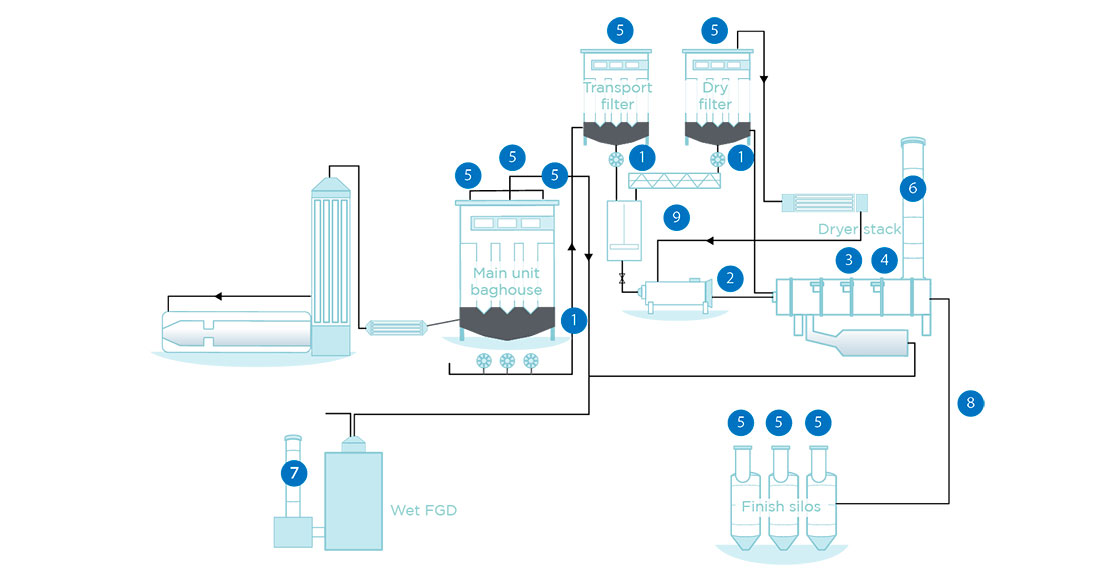

Power generation

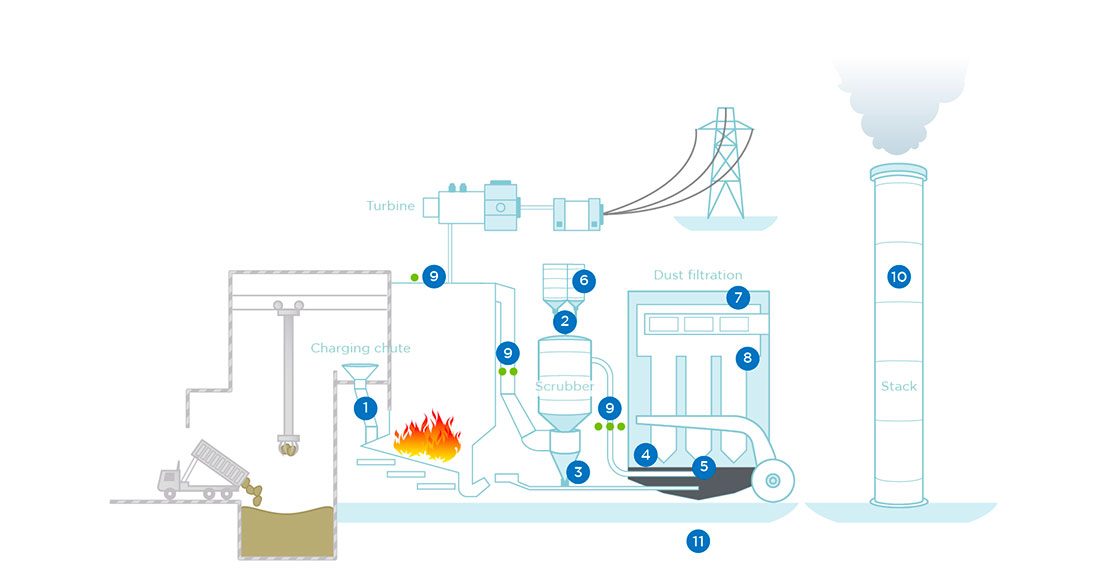

Incinerator plants

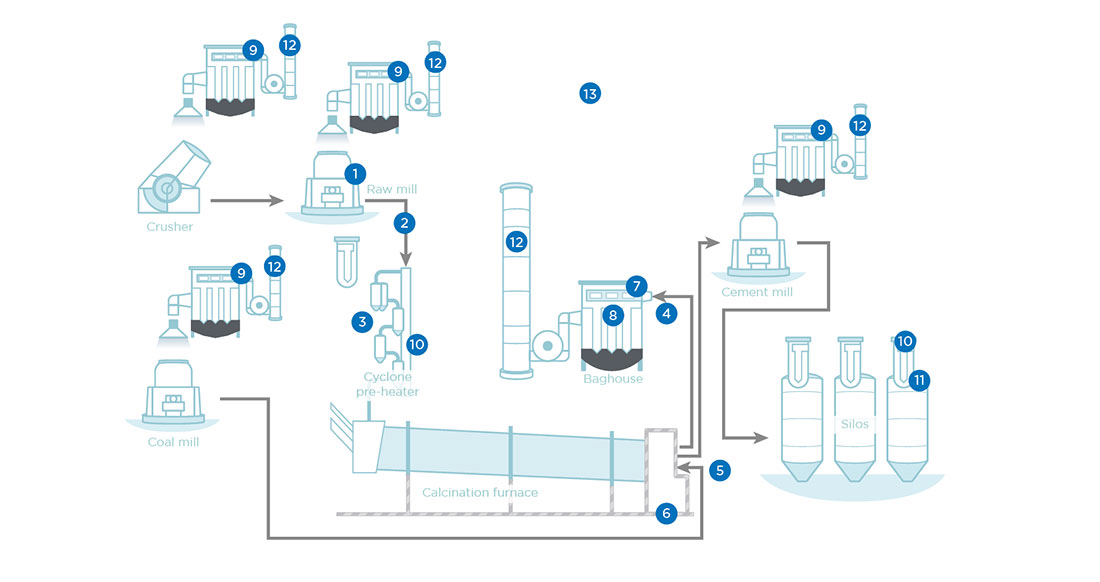

Cement plants

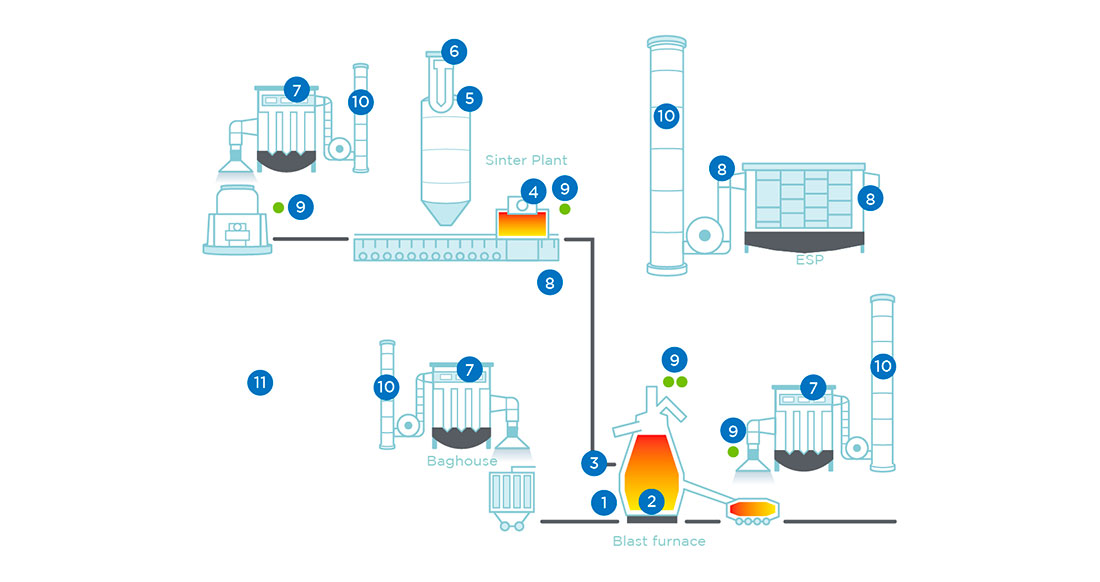

Steel plants

Chemical and petrochemical plants

|

|

CERTIFICATION |

| Our QHSE / Quality, Health, Safety and Environment/ system is in conformity with all statutory obligations and requirements described in the following standardsdržiteli Authorization for the measurement of air pollutants issued by the Ministry of the Environment of the Czech Republic and ISO 9001 Quality Assurance Management Systems, ISO 14001 Environmental Management Systems, ISO: IQ NET 14001 and ISO: IQ NET 9001 |

|